Carrier catalysts are widely used in the chemical and petrochemical industries, such as: Anthraquinone process for hydrogen peroxide production Urea synthesis CO removal from synthesis gas in ammonia production Benzene hydrogenation to cyclohexane Catalytic combustion of low-concentration volatile organic compounds…

I. Systematic Comparison of PGM Recovery Technologies The global recycling of platinum group metals (PGMs) from end-of-life automotive catalysts presents multifaceted challenges. To evaluate competing technologies objectively, we must analyze six critical dimensions: First, regarding recovery efficiency, pyrometallurgical methods consistently achieve…

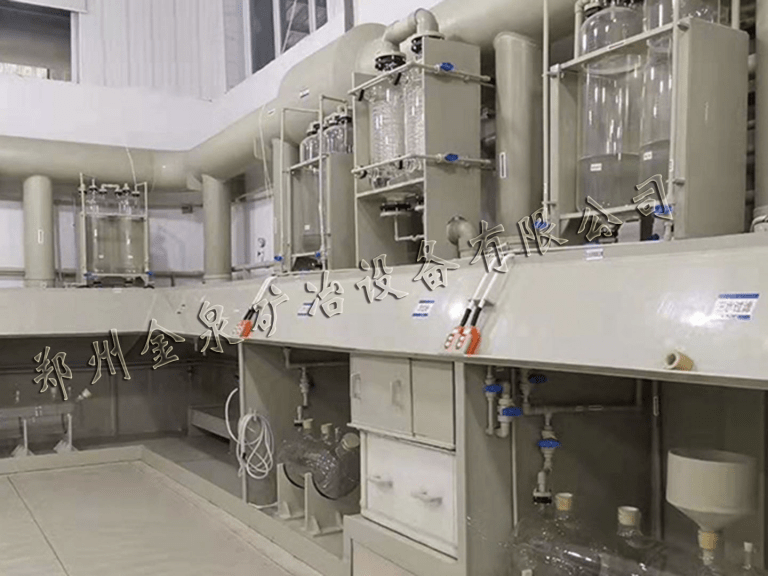

Features of Our Pt/Pd/Rh Recovery & Refining Line Our production line is flexibly designed for client-specific materials and operational preferences, capable of refining and separating Pt/Pd/Rh from feedstocks with >5% purity, yielding final products of ≥99.95% purity. High Recovery Rates…

Gold refining Product Focus: Gold Electrolytic Refining Unit / Machine / System Gold Electrolysis Equipment Gold Refining Plant Key Features: High Purity (99.999%) AC-DC Superimposed Power Supply 1000A/m² Current Density Low Cost (0.02 USD/gram) Target Audience: Small/Medium-Scale Refiners Custom Solutions

Simple gold extraction - gold extraction with aqua regia: 1. Aqua regia preparation cost: hydrochloric acid + nitric acid Function: dissolve gold (reaction formula: Au + HNO₃ + 4HCl → HAuCl₄ + NO↑ + 2H₂O). Ratio: usually hydrochloric acid: nitric…

Platinum Group Metals PGM Refining, including platinum (Pt), palladium (Pd), rhodium (Rh), ruthenium (Ru), iridium (Ir), and osmium (Os), hold immense industrial value due to their critical roles in catalysis, electronics, and advanced manufacturing. However,…

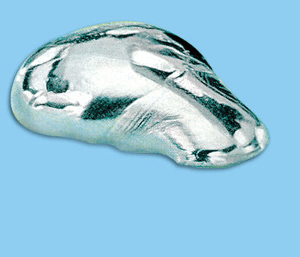

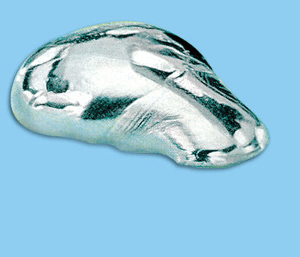

Crude silver electrolysis 9999silver.The raw material of crude silver electrolytic silver refers to the unrefined silver obtained from the preliminary smelting of silver ore or silver-containing waste. Its purity typically ranges from 70% to 99%, and it…

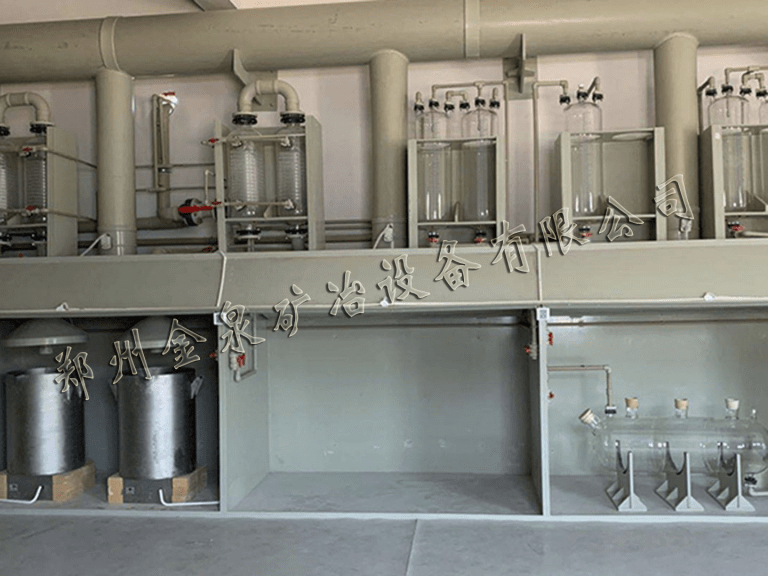

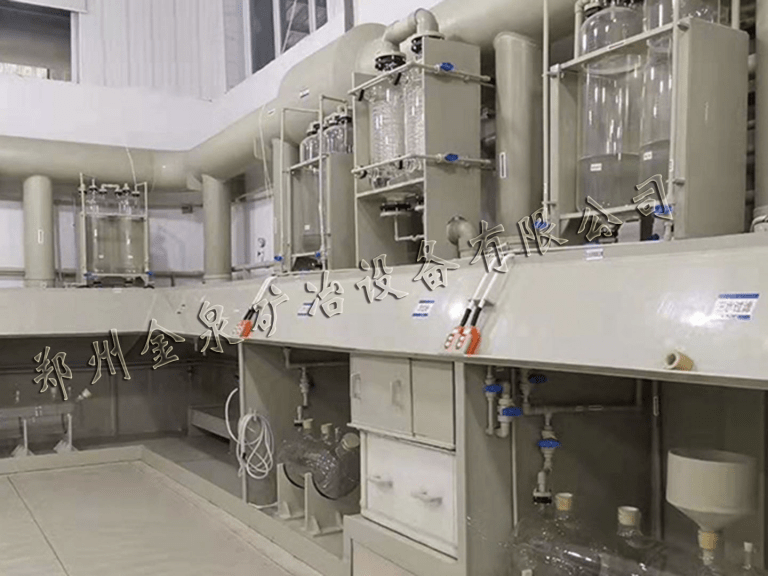

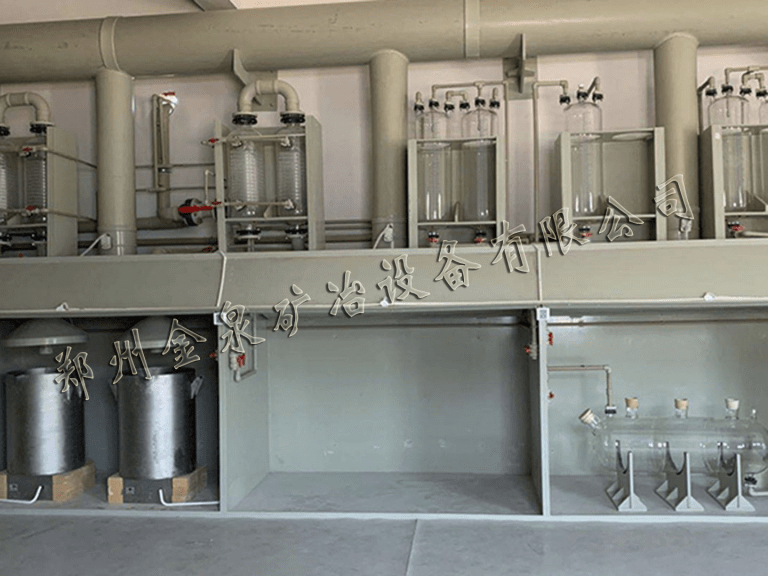

Gold Electrolysis Refining Technology: Principles, System Design & Industrial Applications Gold electrolytic system, including liquid making system, gold anode plate casting system, gold electrolytic system, smelting workshop, exhaust gas treatment system, wastewater treatment system. Anode reaction Au oxidizes…

Electrolytic Gold Equipment Electrolytic Gold Equipment is used to electrolyze crude gold to produce high-purity gold. Crude gold (Au) is oxidized at the anode and dissolved into the electrolyte: …

Jinquan-Gold and Silver Electrolysis Process The gold and silver electrolysis process uses the difference in standard reduction potentials of different metals: Au³⁺/Au +1.50V vs Ag⁺/Ag +0.80V. Selective deposition of target metals, combined with hydrochloric acid (gold)…

Principle of metal electrolysis The basic principle of electrolysis (anode dissolution, cathode deposition), electrolyte composition, purity control, and recovery efficiency. Electrolysis is the process of using electric current to drive non-spontaneous…

Ruthenium catalyst recovery cost? The price of ruthenium catalyst recycling is affected by many factors, including market supply and demand, metal purity, recycling process, etc. As of today, the specific price of ruthenium catalyst recycling will fluctuate with the market.…

Call us now: