Zhengzhou Jinquan Mining and Metallurgy Equipment Co., Ltd. is a comprehensive enterprise. It specializes in precious metal recovery, refining, and purification. The company also provides technical services, equipment installation, and environmental solutions. It has a skilled technical team. The team…

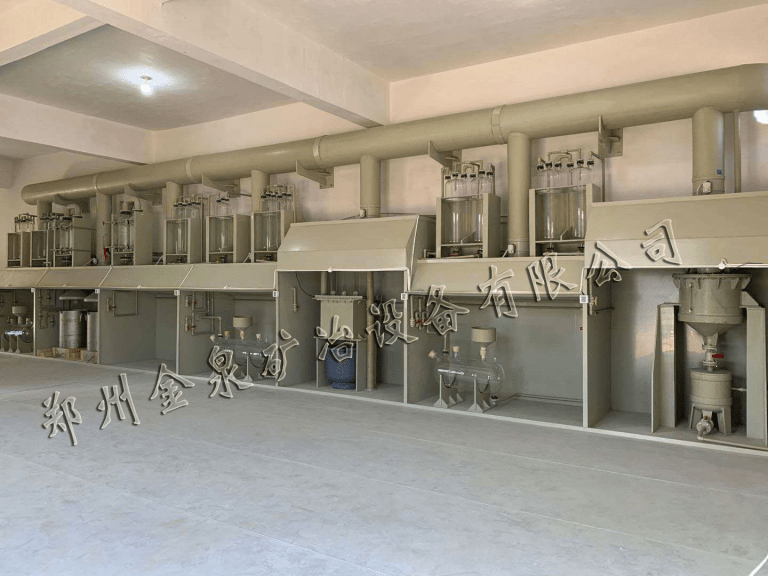

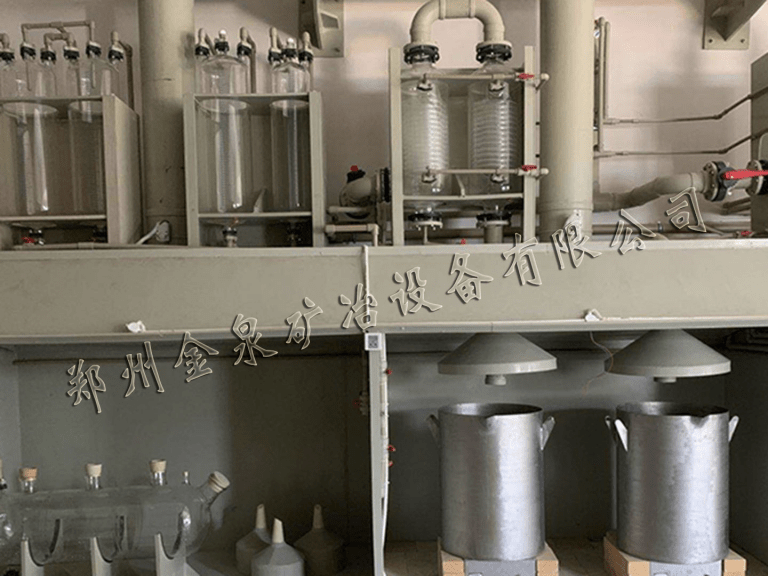

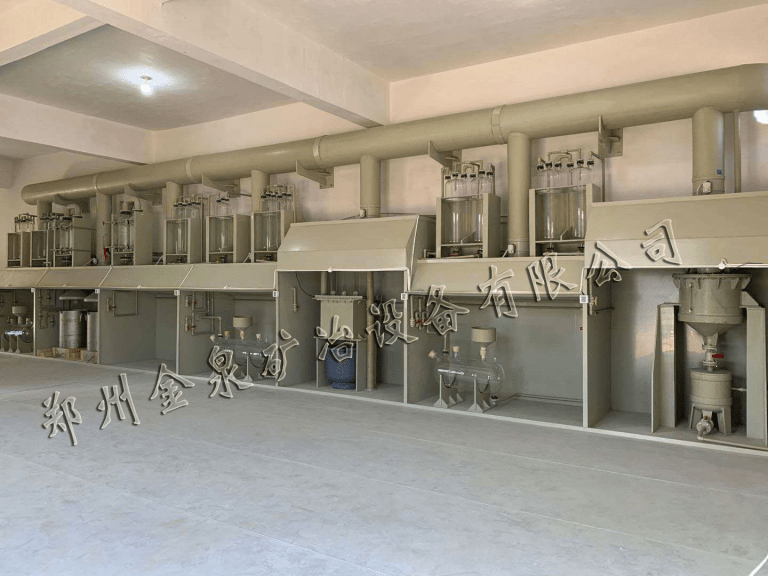

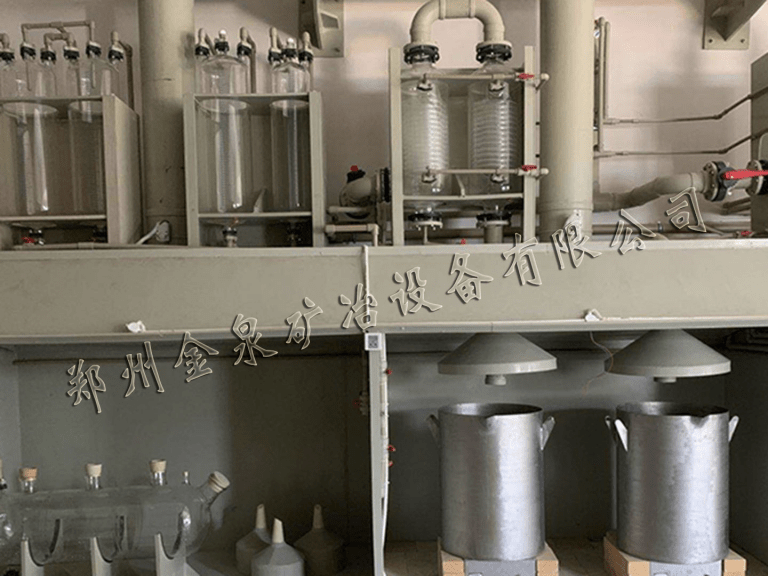

Advanced Silver Electrolysis Equipment: Efficient, Clean, and User-Friendly Unlike traditional silver electrolysis systems that rely on upward ventilation—which typically require high airflow, high pressure, and excessive energy while occupying disorganized space—our innovative sealed downward ventilation system not only ensures zero gas leakage but also delivers energy-efficient operation, a…

Since the 1970s, automotive exhaust catalysts have driven massive demand for platinum group metals (PGMs). In 2008, this sector consumed 118.3 tons of platinum (Pt), 136.2 tons of palladium (Pd), and 23.6 tons of rhodium (Rh). These figures represented 63.7%, 60%, and 110% of that year’s…

High-Purity and Ultra-High-Purity Copper Explained High-purity copper contains at least 99.999% copper (5N purity), where "N" indicates purity level - more Ns mean higher purity. Current standards classify high-purity copper into four grades: HPCu-7N, HPCu-6N5, HPCu-6N, and HPCu-5N. The industry…

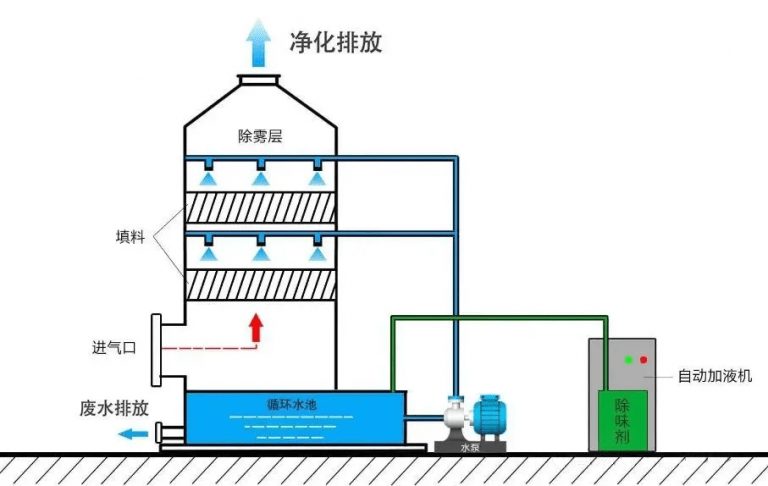

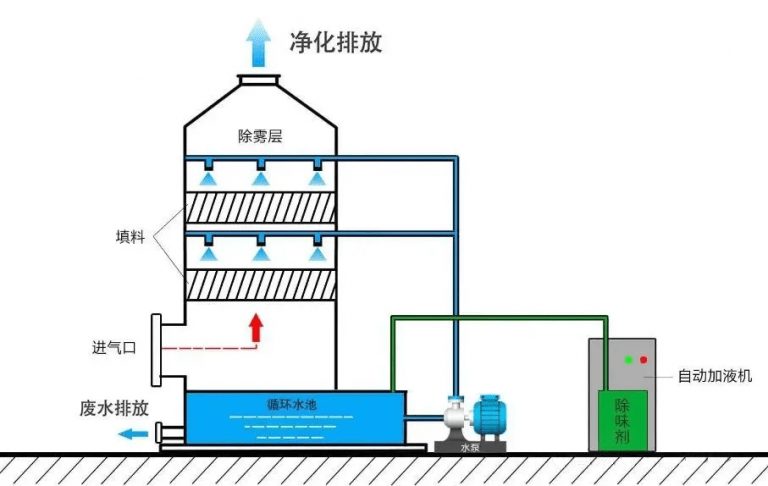

Effective Acid-Alkali Exhaust Treatment for Electronics Factories Electronics factories primarily use scrubber systems to treat acid and alkaline exhaust gases. The process follows a gas-liquid countercurrent principle: Exhaust Collection: Fan systems collect and channel exhaust gases into absorption scrubber towers. Gas-Liquid Reaction: Gases contact the absorbent…

Process Design for Recovering Palladium from Coal Chemical Waste Catalysts This paper outlines a palladium recovery process for waste catalysts in coal chemical industries. Key aspects include: Process Design Overview The method involves roasting, leaching, clarification, resin exchange, complexation, palladium…

To begin with, platinum group metal (PGM) electroplating offers a cost-effective alternative to solid PGM components. By applying thin PGM layers onto base metals, manufacturers can significantly reduce material consumption. Among these, platinum (Pt), palladium (Pd), and rhodium (Rh) electroplating are particularly noteworthy…

Recycling Platinum Group Metal Alloy Scrap Platinum group metal (PGM) alloys come in many forms as scrap. Occasionally, factories collect scrap from a single source with a consistent composition. This material may only suffer from surface contamination or physical damage…

Platinum Recovery from Fuel Cell Catalysts New energy has emerged as a critical industry for sustainable development. Significantly, fuel cells represent one of its most promising technologies. Currently, three main types - PAFCs, PEMFCs, and DMFCs - all utilize platinum…

I. Recovery of Ru from Spent Ru/C and Ru/MgO Catalysts In the ammonia synthesis industry, Ru/C and Ru/MgO catalysts are widely used due to their high catalytic activity and ability to reduce operating pressure and temperature. Process for treating spent…

1. Understanding Catalyst Loss Mechanisms Our Pt-Pd-Rh alloy catalyst operates at 800-950°C under 304-912 kPa pressure. During standard operation, the system loses 0.1-0.15g platinum group metals (PGMs) per ton of HNO₃ produced through three primary pathways: First, high-temperature gas streams…

Platinum-rhodium crucibles, bushing plates, and spinnerets melt glass and glass fibers at high temperatures (1200–1300°C) for extended periods. During operation, some platinum and rhodium oxidize into PtO₂ and Rh₂O₃, which then volatilize and either seep into furnace refractory bricks or become trapped in…

Call us now: