Solution to arsenic in gold mines Currently, there are three methods for extracting gold from arsenic-containing gold mines: 1. Pressure leaching method, which is generally divided into alkaline leaching under normal pressure and high-temperature pressure acid leaching: (1) Normal pressure…

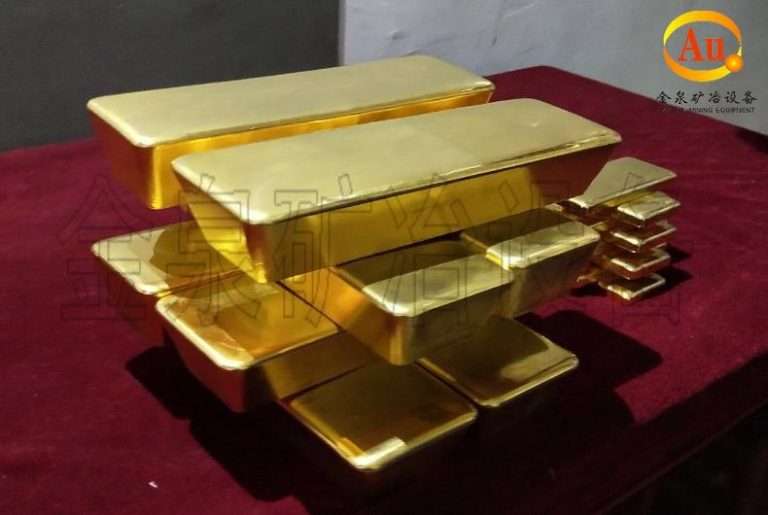

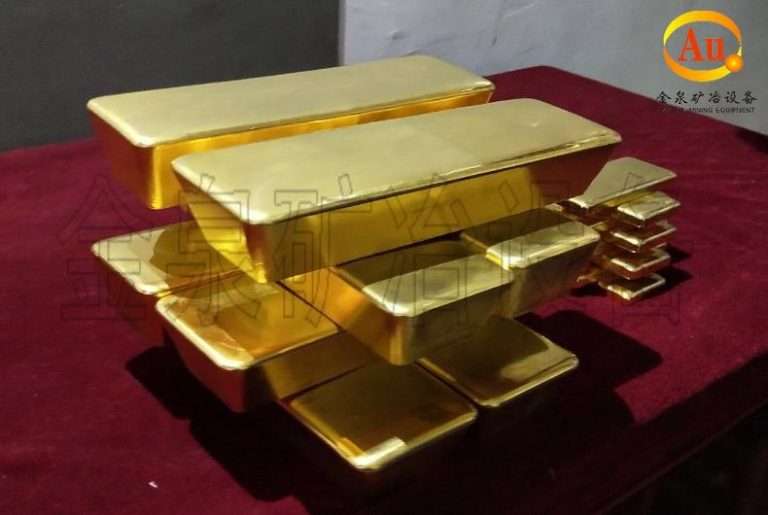

Rapid electrolysis of 99.99% pure gold. By adjusting parameters such as current, voltage, and solution concentration, gold deposition and recovery can be achieved. The graphite electrode is mainly used as the anode to provide a stable electrolysis…

Sources of Gallium and Electrolytic Extraction Methods Gallium (Ga) is a rare metal found mainly in ores and certain compounds. In bauxite gallium often accompanies aluminium in the ore.Gallium high purity extraction relies heavily on…

The Golden Guide to Small Batch E-waste Recovery Electronic products in our daily life are updated quickly, and a large number of old mobile phones, computer motherboards, connectors and circuit boards containing gold-plated parts…

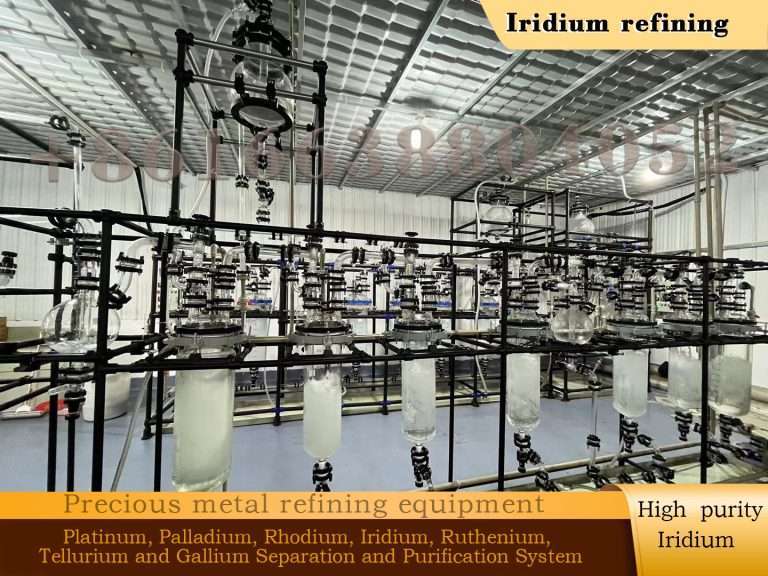

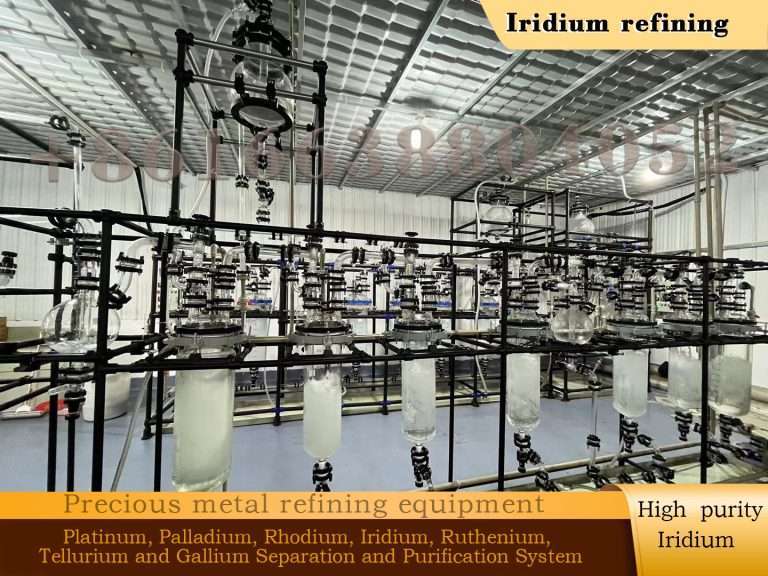

Sources and refining of high-purity iridium I. There are many sources of iridium: recycling of iridium catalysts, recycling of radioactive medical device components, recycling of aerospace components, and high-precision instruments, containing iridium minerals; II. Purification of iridium: (1) Acid leaching:…

Extraction of low-grade gold-containing liquid The process of electrolytic extraction of low-grade precious liquid containing gold is as follows: First, prepare an electrolytic cell and install a stainless steel anode and a metal cathode. Inject low-grade precious liquid containing gold…

Unique properties of tellurium (Te) Density: about 6.24 g/cm³, heavy. Melting point: about 449.5°C, boiling point about 988°C. Appearance: silvery white to gray metal with luster. Reactivity: Tellurium is stable in air, but reacts with oxygentoform tellurium dioxide (TeO₂) at…

Tellurium electrolysis has high-quality characteristics 1. The electrolysis method can produce tellurium with a purity of 99.99%. 2. Tellurium electrolysis is usually carried out at a low temperature of 18°C~60°C, usually does not require very high heat energy, and is…

Extraction of high-purity tellurium by compound electrolysis In the metallurgical process, tellurium exists in the form of compounds. Currently, high-purity tellurium is extracted by electrolysis. Applying current to the electrolytic cell, using anode and cathode reactions, tellurium is deposited from…

Here is a brief description of the copper electrolysis extraction process: Raw Material Preparation: Copper ore is crushed and ground, then converted into a copper-containing leach solution. The leach solution, often treated with sulfuric acid or ammonia, dissolves copper ions…

Universal e-waste recycling technology Incineration is a high-temperature process used to burn away organic materials and plastics from electronic waste, leaving behind metal residues. Smelting involves melting the waste material at high temperatures to separate the…

Separation methods of rhodium-iridium alloy: (1) Acid dissolution Rhodium-iridium alloy is first crushed into fine particles and then placed in a mixed acid containing chloride (such as aqua regia). Iridium reacts with the chlorine in the aqua regia to form…

Call us now: