How to Choose Gold Refining Equipment: A Comprehensive Guide for Optimal Purity and Effi Selecting the right gol is a crimaximum p. We Underst Before choosing any equipment, we first assess the scale of pro, type of,desired. Evaluating Feedstock Type…

Project Overview: Xinjiang Catalyst Recycling Plant Enters Final Phase Zhengzhou Jinquan has successfully delivered and commissioned an annual 6,000-ton precious metal catalyst recycling plant in Xinjiang. The facility processes both ternary and petrochemical catalysts. Key Milestones and Construction Progress By…

Recovery of Platinum, Rhodium, Gold, and Iridium from Spent Catalysts We have been executing a series of contracts for a client in Shangrao, Jiangxi, focusing on recovering precious metals from spent catalysts. The client originally operated a facility processing 600…

In November 2019, we partnered with Shanghai Yaohua Platinum Products Co., Ltd. Their palladium refining and waste gas treatment system processes 10–15 kg per batch. It uses glass reaction vessels and storage tanks. This ensures full visibility of the process.…

Zhejiang Biotechnology Co., Ltd.: Company Profile Zhejiang Biotechnology Co., Ltd. specializes in the development and production of precious metal catalysts. By leveraging the strong R&D capabilities and advanced scientific instruments of Zhejiang University of Technology, we have created unique solvent-free…

Mali 200 t/a Gold Refinery Project Project Overview This initiative will establish a 200 t/a gold refinery in Bamako, Mali's capital. The project will implement its total capacity through two distinct construction phases. Implementation Phases The development will progress in…

This EPC project established a gold and silver refining plant for Sanmenxia Gold & Silver Refining Co., Ltd. Specifically, its scope covered the complete process from workshop design and equipment production to installation, commissioning, and staff training. The plant refines two primary…

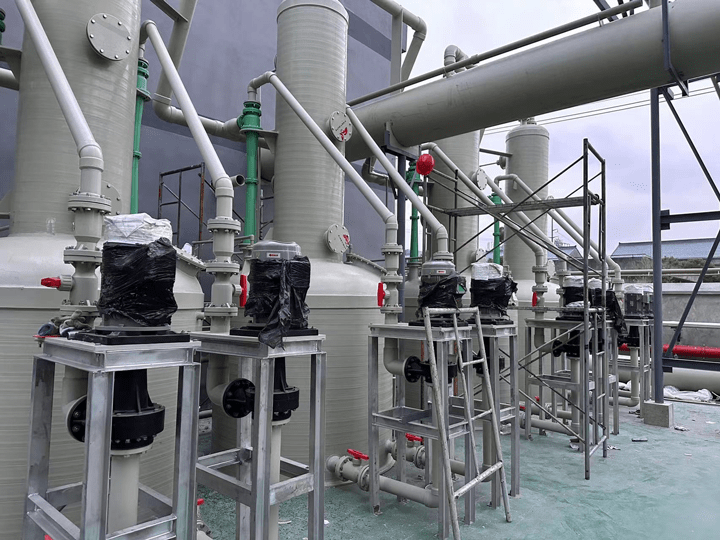

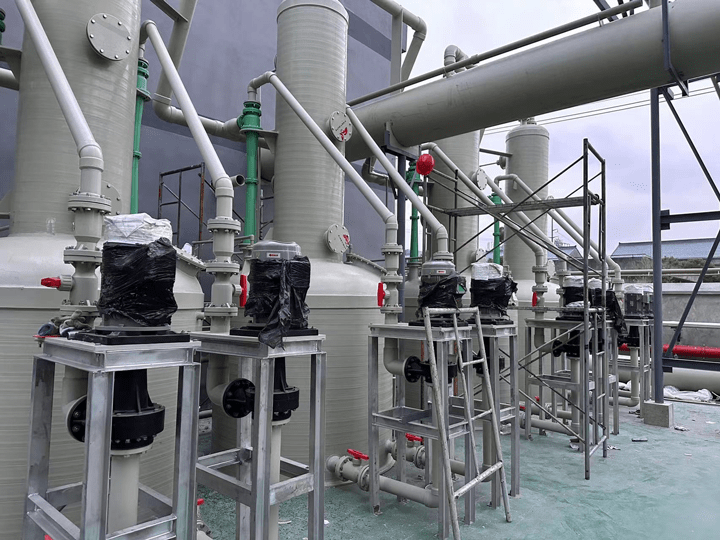

This project launched in October 2019 to treat exhaust gases from the entire precious lead plant. It handles nitrogen oxides and acidic emissions from multiple processes. These include nitrate removal of gold mud impurities, aqua regia dissolution, sodium sulfite reduction,…

Jiujiang Platinum-Palladium Precious Metals Refining Project Project Overview This project officially launched in April 2021. Our team designed it specifically to treat exhaust gases that the silver and platinum-palladium refining processes generate in the smelter’s first workshop. These gases include…

Nitrogen Oxide Treatment Project for Hefei Thin Film Material Co., Ltd. This project began operating in May 2021. It treats high-concentration nitrogen oxide waste gas produced when nitric acid dissolves indium. Data from the client show that the indium dissolution…

Improving Silver Electrolysis Efficiency Through High Current Density To advance silver electrolysis technology, increasing current density is critical. However, this must not compromise silver quality (National Standard Grade 1) or equipment performance. Conventional electrolytic cells face challenges under high current…

To advance silver electrolysis, increasing current density is key—while ensuring high-quality cells (National Standard Grade 1 silver) and stable operation. However, traditional electrolytic cells face challenges. Their conventional electrolyte circulation limits performance at high current densities, causing severe concentration…

Call us now: