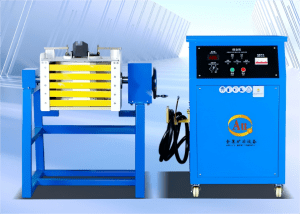

Silver Electrolysis Factory Case

The Thai silver electrolysis factory is a modern smelter mainly using

electrolysis. It uses silver nitrate solution and potential difference to

increase the purity of silver to 99999%.

1. High purity guarantee of silver electrolysis:

When using high current silver electrolysis process for electrolysis, the

current density is above 750A/M², which is 2-3 times that of conventional

silver electrolysis process. The electrolysis time of silver anode plates of the

same quality will be reduced by 60%. In order to avoid the concentration

polarization phenomenon during high current density electrolysis, we designed

and adopted a magnetic pump, and at the same time changed the electrolyte

circulation mode to make the electrolyte flow direction parallel to the plate.

The design of the electrolyte circulation mode of magnetic pump + parallel flow

solves the concentration polarization problem and ensures the quality of electrolytic

silver powder.

2. Optimize the silver electrolysis process:

(1) Use an automatic silver powder scraping device, connected by a crankshaft

connecting rod and driven by a motor, to automatically scrape off the silver powder

precipitated from the cathode plate;

(2) After electrolysis, the remaining residual anode is taken out from the anode

bag and directly placed in the anode titanium frame for non-residual silver electrolysis

to continue electrolysis, without the need to re-cast the anode.

Silver Electrolysis Factory Case

Call us now: