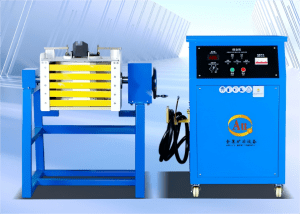

Rhodium oxide recovery process

Detailed process of rhodium oxide recovery: purify rhodium metal step by step.

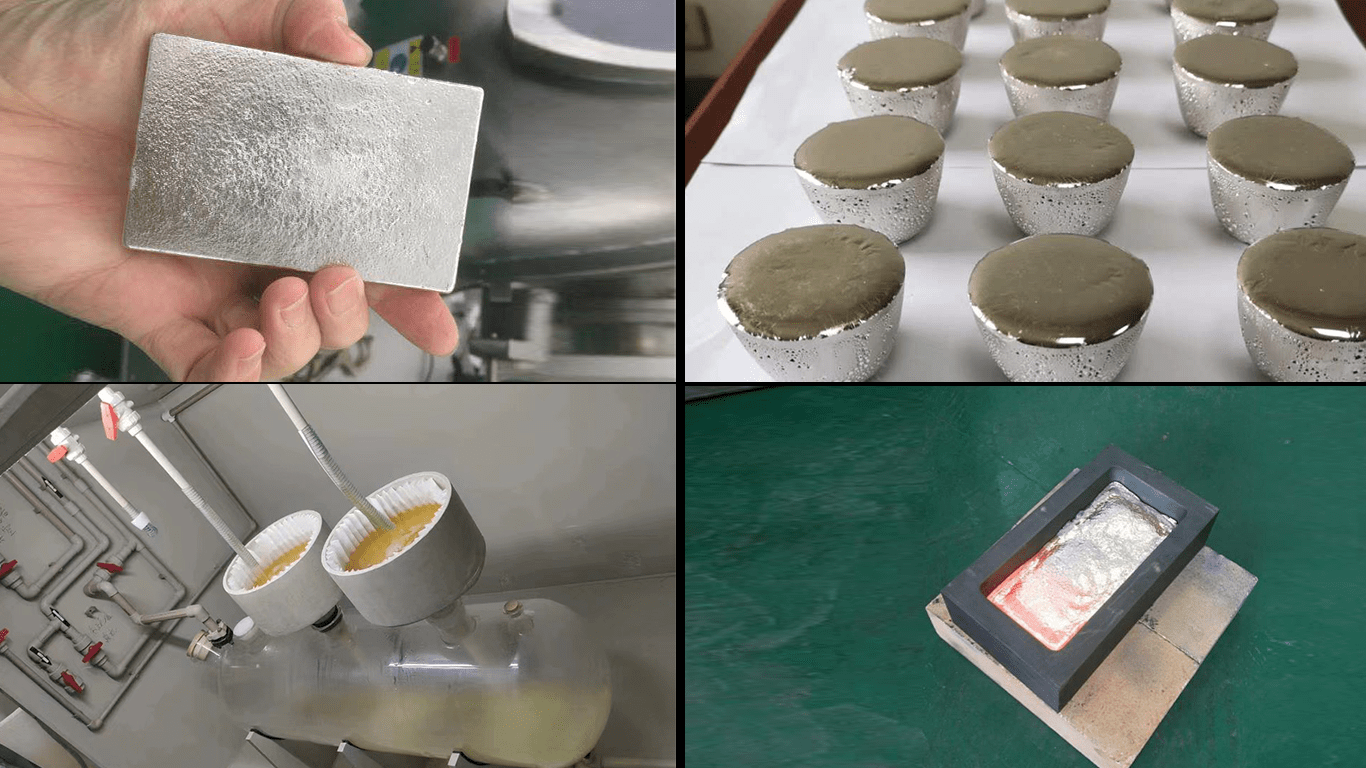

The key to rhodium oxide recovery is how to accurately extract rhodium metal to ensure

that the whole process is efficient and correct. First, rhodium oxide is collected and

prepared for processing. Chlorination or solvent extraction is used to separate rhodium.

Through these standardized methods, technicians effectively separate rhodium in

rhodium oxide from other impurities, preparing it for subsequent purification stages.

The process then progresses through critical reduction phases where chemical engineers

systematically convert rhodium salt into pure metallic rhodium. This carefully orchestrated

sequence ultimately yields rhodium of exceptional purity, though operators must maintain

rigorous technical controls throughout - even minor procedural deviations can significantly

impact final product quality.

The rhodium oxide recovery system not only provides efficient precious metal extraction

but also ensures optimal utilization of finite rhodium resources. During initial processing stages,

workers handle the material in its characteristic powder or granular form containing measurable

rhodium concentrations. The subsequent purification phase centers on precise management of

chemical reaction conditions, particularly during the crucial fluorination stage where rhodium

oxide actively interacts with fluoride compounds to form soluble rhodium salts. Following this

reaction, filtration teams remove insoluble materials to isolate the rhodium-rich solution.

At this critical juncture, extraction specialists employ solvent extraction techniques to

further concentrate the rhodium content. Advanced separation methods then enable technicians

to isolate pure rhodium compounds from the solution matrix. The final stages involve controlled

reduction processes where metallurgists transform these compounds into high-purity metallic

rhodium through carefully monitored thermal and chemical treatments. vido

Rhodium oxide recovery process

Call us now: