Jinquan - E-waste gold withdrawal

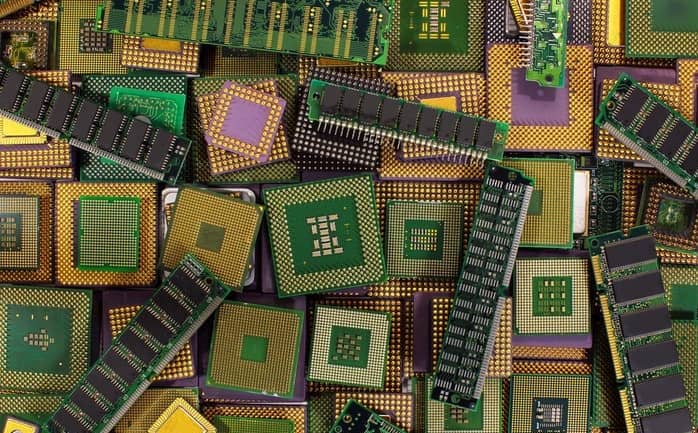

The current process of gold extraction from electronic waste is to enrich

the precious metals in electronic waste into copper alloys through pyrometallurgical

enrichment, and then recover precious metals such as gold, silver, and platinum from

anode mud through copper electrolysis process:

1. Pyrometallurgical enrichment: Electronic waste needs to be at high temperature

(above 1200℃), precious metals and copper form alloys, and other impurities (such as

plastics, ceramics, etc.) form slag separation.

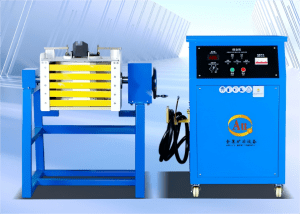

2. Copper electrolytic separation: Copper in copper alloy is electrolytically purified,

and precious metals are enriched in anode mud at the same time. Copper dissolves from

the anode and deposits at the cathode to obtain high-purity electrolytic copper. Precious

metals (gold, silver, platinum, etc.) are insoluble in electrolyte and precipitate at the bottom

of the electrolytic cell in the form of anode mud.

3. Wet metal recovery of gold and silver:

(1) Anode mud pretreatment: Wash and dry the anode mud to remove residual

electrolyte and impurities.

(2) Hydrometallurgy: Use acid (such as nitric acid, aqua regia) or alkali (such as

sodium hydroxide) to selectively dissolve precious metals. Recover precious

metals through chemical precipitation, solvent extraction or electrolysis.

Refining: Further purify the recovered precious metals to obtain high-purity

gold, silver, platinum, etc.

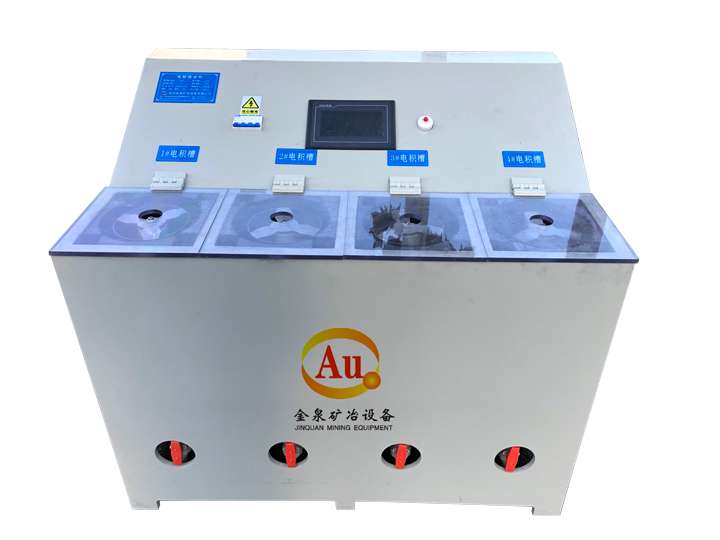

For the gold extraction of dismantled electronic waste, the gold extraction process can

be simplified. After the chemical stripping, the gold is extracted using the electroplating

equipment to complete the gold extraction process of e-waste.

Jinquan - E-waste gold withdrawal

Call us now: