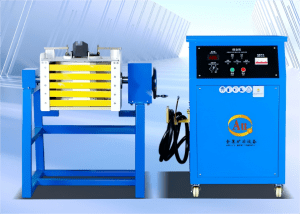

Advanced Silver Electrolysis Equipment: Efficient, Clean, and User-Friendly

Unlike traditional silver electrolysis systems that rely on upward ventilation—which typically require high airflow, high pressure, and excessive energy while occupying disorganized space—our innovative sealed downward ventilation system not only ensures zero gas leakage but also delivers energy-efficient operation, a tidy workshop layout, and a comfortable working environment.

Key Advantages of Our Silver Electrolysis Equipment

1. Stable and Reliable Production Process

To begin with, our system maximizes efficiency and safety through several key features:

-

First, we use reinforced connections between anode/cathode plates and conductive copper bars with stainless steel screws.

-

Additionally, interlocked copper bars provide enhanced stability.

-

Moreover, bakelite insulation between copper bars and the tank prevents electrical leakage.

-

Most importantly, titanium-clad copper contacts on the cathode significantly improve conductivity, reduce resistance, and minimize heat buildup at connection points.

As a result, these innovations reduce production risks, decrease anode slime formation, and lower operating costs.

2. Cleaner Workshop with Reduced Pollution

Traditionally, high-current-density silver electrolysis raises electrolyte temperatures, causing nitrogen oxide and nitric acid mist emissions, which degrade air quality. To address this challenge, we implemented two key solutions:

-

First, we integrated a cooling system to maintain electrolyte temperatures at ~40°C, balancing efficiency with minimal evaporation.

-

Second, we replaced upward ventilation with side extraction and sealed the tank with a transparent glass cover. Consequently, this requires less airflow while effectively capturing harmful gases.

Thanks to these improvements, energy consumption drops significantly, and the work environment becomes much healthier.

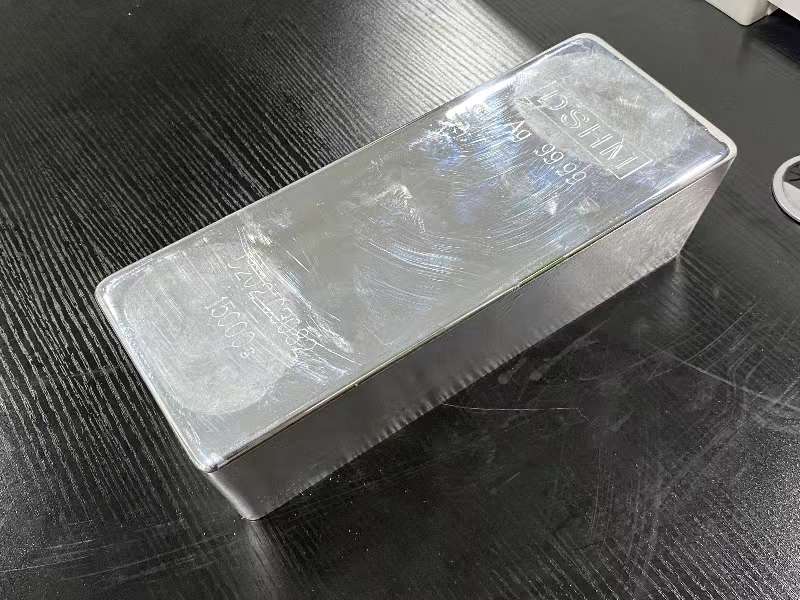

3. High-Purity Silver Powder with Optimized Electrolysis

Unlike conventional methods, our high-current-density process (750+ A/m²—2-3x faster) reduces processing time by 60%. However, high-speed electrolysis can lead to concentration polarization. To prevent this issue, we:

By implementing this solution, we eliminate uneven deposition, guaranteeing consistently high-purity silver powder.

4. Labor-Saving Automation for Smoother Operations

To further enhance productivity, we streamline production with automated features:

-

For instance, automatic silver powder scrapers (bakelite blades on both sides of the cathode) are driven by a motorized crankshaft linkage.

-

Meanwhile, solid-liquid separation at the tank base allows effluent discharge via a bypass before silver powder washing.

-

After that, washed/dried powder transfers directly to casting via an integrated system.

-

Finally, residual anodes can be reused by placing them directly into titanium frames without remelting, cutting downtime and energy waste.

Trusted by Leading Global Refiners

Over the years, our equipment has been adopted by top-tier companies worldwide, including:

-

In China:

-

Zhejiang Hongda Metal Smelting (preferred supplier for China Banknote Printing)

-

SDIC Jincheng Metallurgy, Shandong Humon, and Zhaojin Group

-

Additionally, Zijin Mining, Shuikoushan Nonferrous, and Baiyin Group

-

Internationally:

By combining energy efficiency, automation, and pollution control, our system ultimately sets the new standard in silver refining.

Call us now: