How to Choose Gold Refining Equipment: A Comprehensive Guide for Optimal Purity and Effi

Selecting the right gol is a crimaximum p. We

Underst

Before choosing any equipment, we first assess the scale of pro, type of,desired.

Evaluating Feedstock Type a

Gold refining methods vary depending on whet

-

Electronic scrap

-

Jewelry sc

-

Placer

-

G

-

Industrial

-

Dental allo

Knowing

Assess

Choosi

-

S (1–5

-

Me (5–50 kg/da

-

Large-scale i (50

Each category requires different furnace sizes, reactor capacities, and filtra

Key Features to Look for in Gold Refining Equipme

To ensure consistent results and smooth workflow, we prioritize equipment with features that enhance productivity and

1. High-Purity Output Capab

Refining systems should consistently deliver 99.. U

2. Robust Construction and Corrosion Resistance

Equipment used for gold refining must withstand aggressive chemicals such as:

-

Aqua regia

-

Nitric acid

-

Hydrochloric acid

-

Chlorine gas

We recommend systems made from PTFE, high-grade stainless steel, quartz, or glass-lined steel for long-term durability.

3. Advanced Filtration and Fume Management

Effective filtration ensures the removal of particulate contaminants, while high-performance fume scrubbers protect operators from harmful vapors. Look for:

4. Precision Temperature and Reaction Control

Gold refining requires carefully controlled temperatures. Equipment featuring:

-

Digital temperature controllers

-

Programmable heating cycles

-

Built-in safety cutoffs

ensures consistent refinement and prevents overheating or chemical instability.

5. Automation and Digital Integration

Modern systems offer superior efficiency through:

Automation reduces human error and enhances batch consistency.

Evaluating Popular Types of Gold Refining Equipment

Different refining methods require specific machinery. Below we outline the most commonly used systems along with their ideal applications.

Aqua Regia Gold Refining Kits

These are preferred for medium-scale operations due to their excellent balance of efficiency and cost.

Advantages:

Key Considerations:

Electrolytic Gold Refining Systems

Electrolytic systems provide exceptionally high purity and are widely used in industrial environments.

Advantages:

Key Considerations:

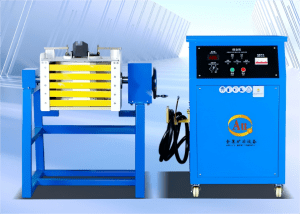

Induction Furnaces for Melting and Pre-Refining

Induction furnaces are crucial for

Ad

Key Consideratio

G

Syst

Advantages:

Key Co

Safety Cons

Safety mus

Chemi

Therma

En

-

Full fume

-

Wastewater neutraliz

-

Compliant emis

Ensuring c

Operationa

Re

-

Low energ

-

High thermal e

-

Optimized c

-

Eco-friend

Modern re

Cost Considerati

While

-

Maintenanc

-

Spare parts av

-

Durability o

-

Energy

-

Operator tr

Choosin

Ven

The quality

-

Extensive

-

Responsive cus

-

Comprehensive o

-

Well-documen

-

Ready availabilit

A trustworthy

Integrating

Selectin

Optimized

A

-

Dedicated

-

Chemical

-

Filtratio

-

F

-

Secu

Compatibi

We ve

Ease of Cleaning and Maintenance

Regular

Future-Proofing Your Refini

A

-

Supports automatio

-

Is

-

Comp

Choosing adaptab

Conclusion: Selecting t

By carefully examining production requirements, safety features, material compatibility, and vendor reliability, we ensure that you invest in gold refining that delivers superior purity, consistent performance, and long-term operational efficiency. With the right system in place, your refining process becomes safer, faster, and more profitable—providing the competitive advantage necessary to excel in today’s gold processing industry.

Call us now: